Revolutionizing the Palm Oil Industry: How AI Vision Technology Tackles Manual Labor Challenges and Optimizes Yield through Stripped and Unstripped Bunch Detection

AI Vision technology is a powerful tool that can help the palm oil industry in Malaysia to tackle the challenges of manual labor, by automating the tedious and time-consuming task of bunch detection for stripped and unstripped bunches

The palm oil industry in Malaysia is a vital economic sector that provides jobs and income for millions of people, but also faces significant challenges, one of them being the reliance on manual labor. However, the implementation of AI vision technology can help tackle these challenges and improve the efficiency and productivity of the industry.

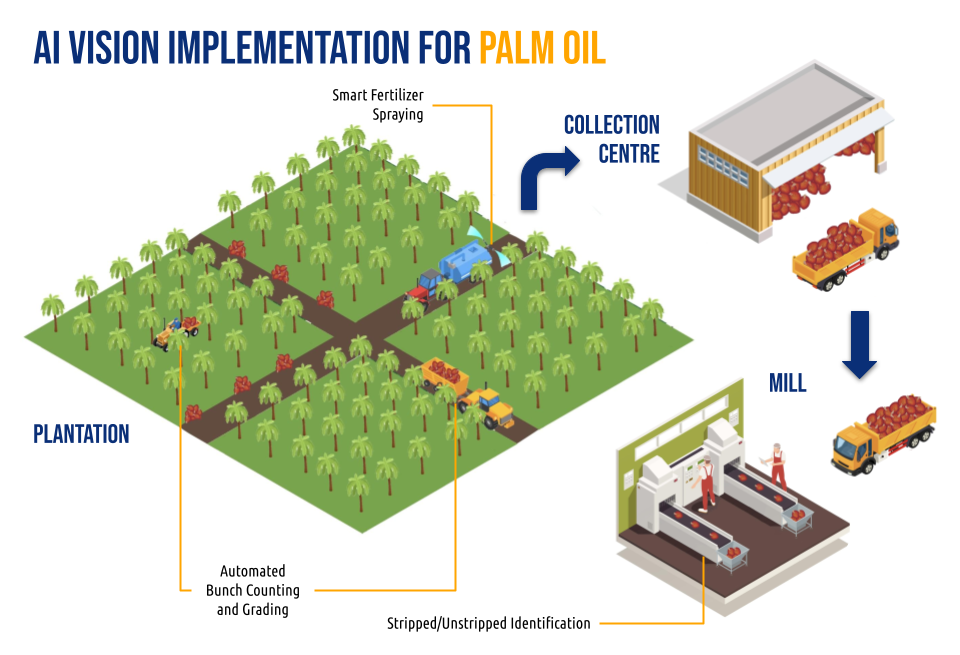

One of the main advantages of AI vision technology in the palm oil industry is the ability to automate tedious and time-consuming tasks, such as tree counting, bunch detection, and mapping of large plantation areas. This reduces the workload on human labor and enables them to focus on more value-added tasks.

With VisionTrack, Tapway has been helping palm oil companies to detect and identify stripped and unstripped bunches in real-time, by using cameras to capture images of the bunches and then analyzing them.

Tapway VisionTrack uses a custom-trained object detection model to detect stripped and unstripped bunches that are moving along a conveyor belt. The system counts the number of unstripped bunches detected, and alerts the palm oil company if the aforementioned count goes above a specific threshold. While doing so, Tapway employs various methods in the inference pipeline to ensure that the predictions made are consistent and accurate.

Tapway VisionTrack has achieved >95% counting accuracy for detecting all types of bunches and >90% counting accuracy for unstripped bunches specifically which resulted in the reduction of classification time to 100 bunches per minute and the increase in the productivity of the operations.

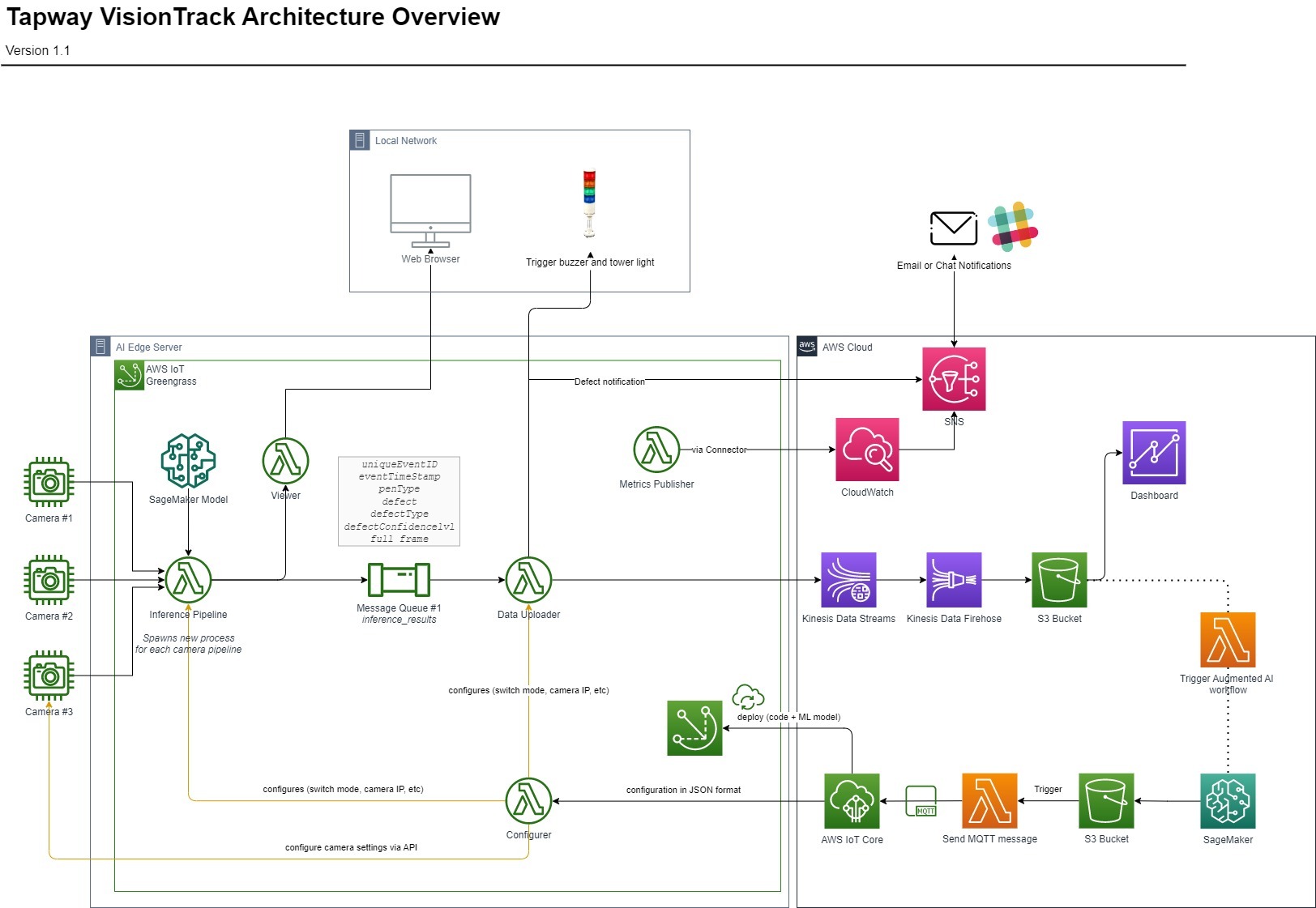

In achieving this, Tapway is using AWS SageMaker for training object detection models due to its ease and convenience and AWS S3 to store all project-related files such as the trained models and inference image datasets. SageMaker trained AI model is delivered to the edge server on site via AWS IoT Greengrass where it contains the AI inference lambda, web viewer lambda, data uploader lambda, metrics publisher lambda and other functions. Through metrics publisher lambda with integrated CloudWatch plugin within Greengrass container, server health metrics and logs are easily sent to AWS CloudWatch for remote monitoring and alarms are set to trigger notifications to the client via AWS SNS. Using AWS IoT Greengrass, frequent edge software updates can be delivered seamlessly. Inference metadata is sent via stream manager to AWS Cloud via Kinesis Data Firehose and Kinesis Data Streams before saving to AWS OpenSearch. A cloud dashboard is delivered to the client using Kibana which is part of AWS OpenSearch.

Furthermore, AI Vision technology can also be used for automated fertilization which reduces costs and improves crop yields and quality. It can also be used to automate the process of monitoring the growth of palm trees and detecting potential issues such as pests, weeds and diseases before they become critical, which can prevent crop loss and wasted resources.

In conclusion, AI vision technology is a powerful tool that can help the palm oil industry in Malaysia to tackle the challenges of manual labor, by automating the tedious and time-consuming task of detecting stripped and unstripped bunches. By using cameras and sensors to capture images of the bunches and analyzing them with sophisticated algorithms, this technology can improve the accuracy and speed of detection, reducing the margin of error and increasing the productivity of the operations. It can also help to optimize the yield and detect stripped bunches, which helps to track and prevent issues. This technology can help the industry to increase yield and quality while reducing the workload on human labor, making it a valuable investment for the industry to improve efficiency and productivity.

Experience the game-changing benefits of our advanced license plate recognition system and transform your security and access control – Request a demo now!

Insights